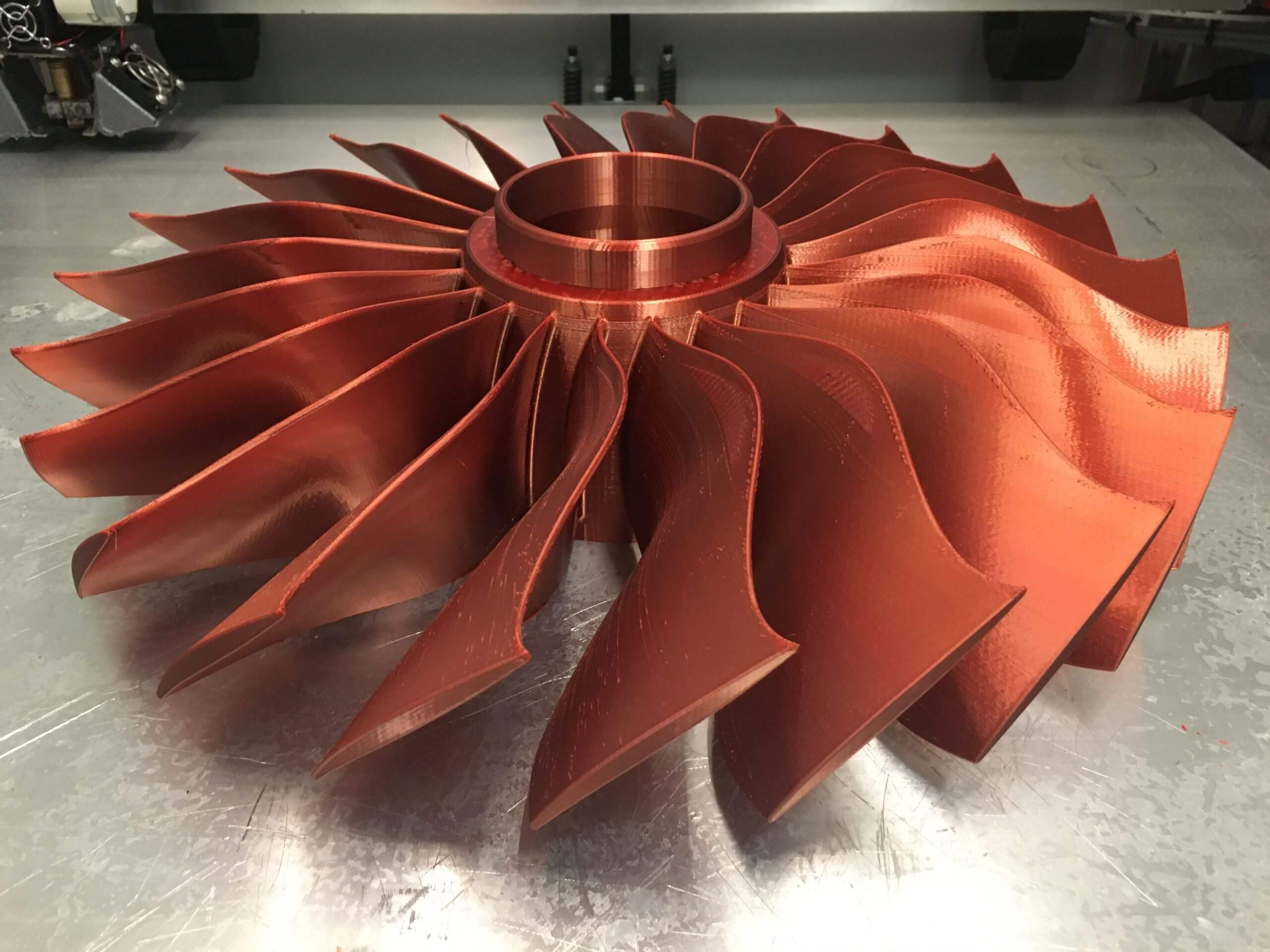

Large format 3D prototype

Prototyping is the basis for a large-scale project. The production of prototypes allows the production of a first typical model to be launched, in order to correct any anomalies linked to the design. This step is the first step in the realisation of your project. Making prototypes of your products thanks to the development of injection and 3D printing techniques allows you to test your part in complete safety, before launching the complete production process on series of products at significant costs. 3D printing is a technology that will and has already changed the world of manufacturing, as including it in the design process through prototyping means eliminating inaccuracies and carrying out full-scale tests before the final result. Additive manufacturing in resin, plastic, metal or other materials is one of the most effective tools for determining the surface of a product, its final appearance and whether or not it matches the initial models, with laser precision. All these tests ensure the quality of the final product, and are therefore indispensable tools for companies, especially in industry. 3D printing using high quality printers, in order to obtain realistic and precise prototypes, ensures the final functionality of its products. This is one of its many advantages.

Prototype your projects in large format 3D

You have a parts project and would like a prototype to validate your concept and, if necessary, make adjustments or carry out life-size tests. Then go for 3D prototyping!

We are ready to listen to your 3D prototyping projects with many options:

- large format 3D printing : 3D printing allows the creation of large volume parts in order to transform the starting scale of different products.

- CNC machining: it is defined by the fact of machining parts thanks to a 3D file that will guide the printer throughout the manufacturing process.

- tools and moulds for thermoforming : 3D printing makes it possible to go beyond the simple machining of parts. It makes it possible to manufacture customised moulds for thermoforming. 3D printing has developed very precise and functional moulding technologies, allowing companies to use moulding to have customised mould models, with any type of material. This is one of the most popular applications of 3D printing used by companies.

- Finishing according to your request with many solutions to adapt to your needs : once the printing is finished, it is time to move on to the finishing stage. This begins with cleaning, followed by visual enhancement, assembly or even painting in some cases.

The aim of this entire process is to produce exceptional prototypes of outstanding quality and realism. The manufacture of the prototypes is supervised by our teams throughout the printing process. Various techniques are used for 3D printing, including SLA printing, FDM printing and SLS printing.

High quality materials for your prototypes

The manufacturing process does not only supervise the technical aspects of the design. Pami3D's expertise also lies in advising our customers on the choice of materials, for example. Indeed, it is our responsibility to offer you materials adapted to your needs. The advantage of the 3D printer is the fact that it can produce parts combining transparency and hardness but also flexibility and resistance. 3D printing is carried out using plastic materials that meet your specifications. 3D printing allows the production of strikingly realistic objects.

From product design to 3D prototype

As an essential step in a product launch, we produce 3D printed prototypes for you to get as close as possible to the final product. This printing is produced at real scale, reduced or enlarged.

Your 3D prototype, once finalised thanks to its similarity to the final product, allows you to validate the project with your teams and even with some of your customers in order to obtain feedback before the final launch of your product. This prototyping highlights on the machined parts, the possible failures which can harm the production or on the contrary reassure on the stage of manufacture of the object.

Our teams follow you step by step during the design of the 3D file with a technical drawing or a scan of your initial project. The 3D printers are programmed from the data collected, in order to produce different prototypes that will allow the initial version to be improved.

3D prototype, the last step in the process before production

From a marketing point of view, prototyping gives a taste of the final product as it is a faithful reproduction of it. 3D printed prototypes allow you to study not only the technical and functional aspects but also the

- Design

- Geometry

- Volumetry

Once the prototyping is complete, your teams can study the various parameters related to the 3D object and the production of the final object.

If you wish to create a 3D printing prototype, entrust us with your project and ask for a free, no-obligation quote at devis@pami3d.com

Discover some of our large format 3D prototypes

Why choose us?

Pami3D is the specialist in large format 3D printing, and allows you to give volume to your creations and visual impact to your offer